See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Do you know that there are several ways for you to increase the blower efficiency of industrial systems for processes that involve:

The first place to investigate, when looking to improve efficiency, is to identify all the factors that will help reduce energy consumption of the blower. This will generally provide the biggest gains. Then you can identify other factors that will reduce maintenance and improve the industrial system performance.

Read to what tips we provide in this guide.

Increase blower efficiency in these industrial processes

How do you recognise the signs of an inefficient industrial blower system before it becomes irreparable?

Top causes of broken blowers

Have you noticed a sudden increase in your operating cost? This is probably the result of:

If you don't have in-house expertise in-house you will need an expert on industrial blowers to conduct a comprehensive inspection. Feel free to call us for help on 1300 721 458.

Increase blower efficiency to reduce operating and maintenance costs

Does your industrial blower produce a high level of noise? If so, you need to get it checked.

High noise levels produced by a blower are often associated with an oversized blower fan or one inappropriate for the specific application. It is vital that blowers operate within a reasonable range of their best efficiency point (BEP).

Increase blower efficiency to reduce level of noise in the workplace

Does your industrial process suffer from inadequate air flow? This may be due to inadequate balancing within the system.

Do you find it difficult to adjust the flow rate of your production? This can be from poor duct design or configuration in your system. Allow an expert to handle this for you. Send us a message.

Increase blower efficiency to improve air flow

The following are the main causes of industrial blower system inefficiency.

There are a number of reasons why a blower can fail to rotate. Some are obvious; others are not.

Rust in the blower means thorough inspection and cleaning is required. You can do this yourself, or you can call on an expert maintenance team like us. We can do the servicing for you quickly and efficiently. Further, we can use our industrial experience to identify other faults and make repairs while doing the blower inspection and cleaning.

Damaged motor winding in your blower system requires a blower expert that is a qualified electrician to inspect and repair the damaged motor.

A blower expert that is a qualified electrician is required to inspect and fix improper wiring connections within the motor. It is best to contact your blower system supplier or an expert maintenance team, such as us, with the expertise to properly assess and correct the problem.

This could be caused by a pipe leak, broken belts or broken drive couplings. To help diagnose the cause of this problem check the valve and/or see if there are any loose connections.

If you don’t have an in-house maintenance team to do the repair and maintenance, feel free to call us today on 1300 721 458 today.

There are several major conditions that will cause your blower to exceed maximum vibration. These include:

If the system is vibrating, turn off the power and inspect the bolts, double-check the foundation base and the tension of the v-belt drive. If you are unfamiliar with these parts or lack the expertise, send us a message for assistance. Our maintenance team will be happy to help.

Excessive blower temperatures are caused by one or more conditions that are easy to identify.

If your blower is operating at very low speed, this will create inefficient conditions. These will labour the process and make the blower work harder. To ensure temperature issues do not develop it is vital to run the blower at the speed for which it is designed.

You should regularly replace your air filter to avoid blower inefficiency due to dirty air filters.

Do you have problems remembering when your air filter is due for inspection and maintenance?

Our efficient SITE system helps you remember when your system is due for maintenance. Watch this video on the Pneuvay SITE system to learn more about it.

You will need an expert's opinion to determine if your impeller needs replacement. Talk to us about it.

Restricted inlet air flow can be caused by obstructions or a closed valve. You need to ensure your blower system is checked regularly to identify when a restriction starts developing. It is best to have an expert such as us to pinpoint the cause and resolve the restriction.

Aside from fixing an inefficient industrial blower system, you may also follow these steps to help reduce your energy costs and increase blower efficiency.

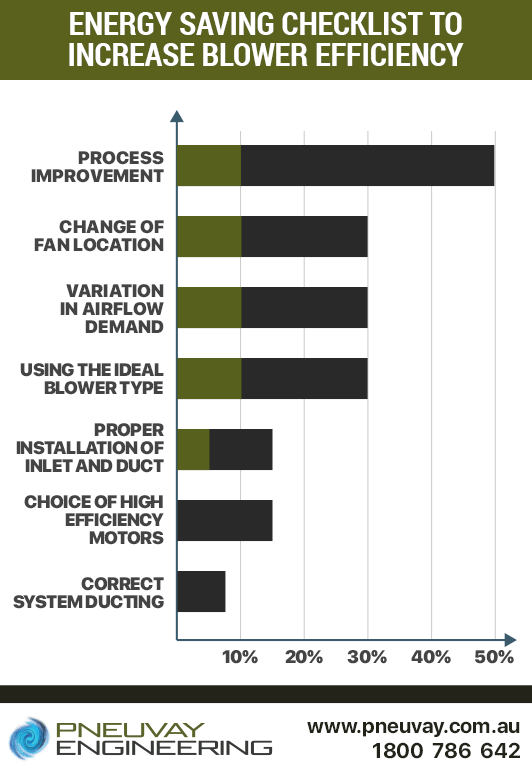

If the blower is used on a periodic rather than continuous basis, make sure it is shut down when not required. It is also important to re-evaluate and verify the exact requirements needed for your industry process. Older blowers within your systems may generate inefficiency by becoming oversized or under-capacity. Checking your process can reduce your energy consumption from 10 to 50 percent.

Relocating your blower to reduce its length of runs and straightening bends can help you reduce energy consumption by 5 to 30 percent.

Using variable pitch axial fans (VSD) and multi-speed motors in your blowers can reduce energy consumption from 5 to 30 percent.

Inefficiency occurs when blowers are oversized or under capacity for the industry process. Knowing the type of blower that will deliver the required pressure and flow characteristic will provide energy savings of between 5 to 30 percent.

Evenly cut the flow of air into your blower by installing turning vanes as needed. You should check if fixed blades can be installed to straighten the airflow. These modifications can help reduce your energy consumption from 5 to 15 percent.

High efficiency and durable motors, although expensive compared to standard motors, will prove more economical in the long term. They can help reduce your energy consumption by up to 15 percent.

Choosing quality motors for blowers will also reduce the maintenance requirement over the life of the blower.

If your system is not using tubular ducting, then you should investigate if it is feasible to change form. Tubular ducting uses the least amount of material, lowest pressure drop, lowest velocity and smoothest air flow. Using tubular ducting reducing energy consumption by up to 7 percent.

Energy saving checklist to increase blower efficiency

Let Pneuvay help you reduce your energy costs by making sure your industrial blowers are designed and working efficiently. If you need repairs or maintenance for your blowers, we can assist. We can also help if you need a new replacement blower system for your factory, manufacturing or food processing plant. Talk to us today.

Get social with us and see the latest news items from:

Pneuvay Engineering is proud to announce we are the official sole agent for Vortex Australia.

This is a great development for the Australian pneumatic conveying industry.

Read on for more.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags