See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Wednesday, March 22, 2023

Are you looking for some dust collection tips and guidelines to ensure your dust collector performs efficiently? Then you have landed on the perfect page.

Let’s explore the world of dust collection systems. Read on for some expert tips and advice on how you can keep your dust collectors functioning efficiently.

Dust collection tips and guidelines to remember

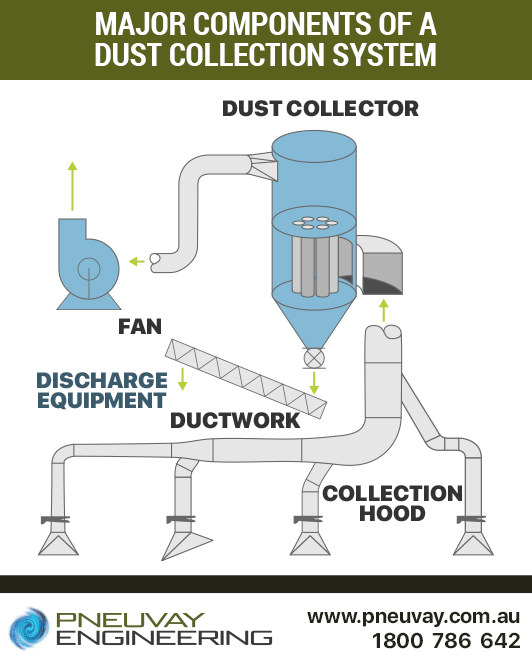

A dust collection system has five major components, namely:

Major components of a dust collection system

One of the best dust collection tips we can offer is to take great care of these components. This entails monitoring the:

Here are some tips to ensure the efficiency of these components.

Collection hoods are the entrance to your dust collector system. Ensuring they are working efficiently is paramount.

If the capture velocity is too high at the collection hood, excessive particulates will get into the dust collector towards the filters. The filters will then be subjected to heavier dust loading than they are designed for. This will quickly wear out the filters and require more cleaning energy.

Capture velocity is the speed of air at the hood opening. This overcomes opposing air currents and captures dust to flow into the hood. Duct velocity, on the other hand, is the speed of air inside the ductwork.

An efficient collection hood should have a duct velocity equal to or slightly greater than the minimum air velocity required to move dust particles in the air stream. The flow pattern and capture velocity must be sufficient to control dusting without collecting excessive dust.

If the capture velocity is too high at the collection hood, excessive particulates will get into the dust collector towards the filters. The filters will then be subjected to heavier dust loading than they are designed for. This will quickly wear out the filters and require more cleaning energy.

For optimal dust collection hood efficiency, ensure:

Hoods should be able to handle capture velocities of 1 to 15 metres per second (200 to 250 feet per minute). It is vital to make sure collection hoods are enclosed properly to prevent excessive outside air being pulled into the system.

The ductwork is your dust collection system’s highway. To ensure it works efficiently you need to check the following key parameters.

For most applications the proper dust velocity is between 15 to 20 metres per second (3,500 and 4,000 feet per minute). If the velocity drops below 15 metres per second, dust will fall out into the airstream. If it goes above 20 metres per second , it will result in duct abrasion, particularly in the duct branches and elbows.

For expert consultation and advice, schedule a consultation with our team of experts today. Call us at 1300721458 .

The size of your ductwork heavily influences the result of your dust collection system.

Ductwork that is too small results in a high velocity rate in the duct. This speeds up wear and tear on the ducts.

Plants with small ductwork have holes and patches. Some plant owners think patching these ducts is the best solution. A more efficient solution, however, is gained from designing the ductwork properly.

Overly large ductwork results in very low velocities. This produces dust fallout and build-up in the duct, which creates maintenance problems. The dust build-up reduces the cross-sectional area of the duct. This affects the overall airflow and air velocities of the collection hoods.

Uneven loading of ductwork causes abrasion of the filters. In extreme cases it even results in wear through the dust collector hopper walls.

Ductwork into the dust collector should have a straight run of at least eight diameters. This ensures the air and dust loading is evenly distributed over the whole dust collector.

Several factors have to be considered before adding vent hoods and ductwork. Answering the following questions will point to the appropriate solution.

Adding and installing ductworks seems to be the easy fix. Without the right design and planning, however, you may soon find yourself needing to use turning vanes just to ensure dust and air are distributed evenly. To avoid additional workload for your maintenance department, it is better to have the ductwork designed correctly. Talk to us if you want to redesign your dust collection system's ductwork.

Ductwork maintenance tips for dust collector systems

There are two key points you need to consider with your dust collector.

The relationship between the amount of air flowing through the dust collector and the total amount of media is based on the following factors:

Talk to us for your dust collector maintenance needs.

This refers to the velocity at the bottom of the filter bags. If this is too high, the capture dust will not fall effectively into the filter bags. For this reason many dust collection manufacturers recommend a velocity of less than 300 feet per minute (1.5 m/sec).

There are two ways of fixing an excessively high can velocity.

High can velocity causes higher than desired differential pressure and cleaning cycles. This results in filter bag abrasion caused by too much airflow through the dust collector housing. To fix this, you can consider increasing the house size of the dust collector or, conversely, reducing the airflow.

Regular replacement of filter bags improves bag cleaning, whilst using cages with shorter pleated filters greatly improves efficiency. This lowers the velocity below the bags, thus reducing corrosion. This, however, must be done on a case-by-case basis and based on the recommendation of an expert dust collection maintenance team.

Consistent differential pressure yields consistent airflow and velocities throughout the system. On average, dust collector systems operate very well between 127 and 132 mm (5 and 6 inches) of water column pressure (WC). Adjusting the cleaning controls to differential pressure is, therefore, a simple and inexpensive way of ensuring your system’s efficiency.

The fan is the engine that supplies energy to the dust collector system. It is, therefore, very important to ensure it functions efficiently.

The size of your fan dictates the amount of air volume of your dust collection system. If your fan is undersized it cannot produce the desired air volume. It is forced to deliver more air volume than needed. This puts unnecessary stress on the whole system, resulting in more frequent maintenance problems.

Talk to us if you feel your dust collection fan's size does not fit your requirements. We can design a more efficient system for you.

Hoppers filled with dust create a circulating dust load. This results in:

To prevent this, air locks need to be placed at the bottom of each hopper. This prevents dust from flowing back through the hopper.

It is important to check all your dust collection components when experiencing airflow or dusting problems. Do not settle for a quick fix in one area.

Investigate all five components to properly evaluate your system's condition. Understand and strictly follow the guidelines provided by your dust collection manufacturer. Create and implement a reliable dust collection system.

Most importantly, talk to an expert dust collection maintenance team who are skilled and experienced to perform all necessary repairs. Call us today at 1300721458 or send us a message for your dust collection maintenance and filter replacement needs.

Feel free to check out our latest posts on LinkedIn and Facebook.

Get social with us and see the latest news items from:

We recently made an exciting visit to Vortex in the USA to enhance our capabilities as a regional agent for their products.

Discover the valuable insights we gained and why we are proud to partner with Vortex!

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541