See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Friday, January 31, 2020

Understanding the differences between dust collectors and industrial vacuum systems is essential. This is something frequently discussed by plant managers and operators when assessing such options for their operation. So how are they differentiated?

The differences are easily understood, and you will achieve savings through ensuring you use the appropriate system for your particular operation. Relative to industrial ventilation, there are two options currently used for moving air, each relevant to different requirements. The specific disparities between the dust collector and vacuum systems are what need to be considered to ensure fit for purpose. See below for discussion of these.

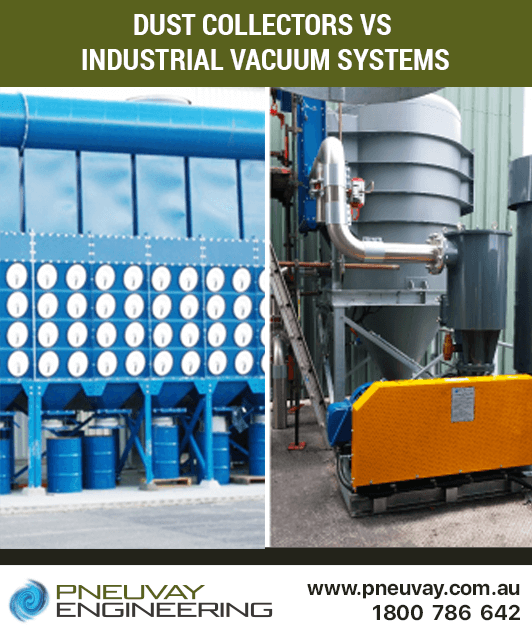

Dust collectors vs industrial vacuum systems - why they are not the same and how they are different

Industrial vacuum systems work on the basis of low volume, high pressure (LVHP). Consider domestic or motor vehicle vacuum cleaners. Vacuum cleaners for use in industry have far greater intake velocity – can be up to 50m/sec – and an air mover with tight mechanical tolerances. The vacuum hoses are generally 38mm to 50mm diameter and 7 to 15m long with air volume of 207 cu.m/hr per user. This is typically termed a ‘low volume high pressure’ (LVHP) system.

Dust and debris is removed by vacuum from walls, floors, under and around machinery/equipment and from under other areas such as under-conveyor bulk piles and transfer points. A central vacuum system able to do this will generally use between five and seven HP per operator. Such a vacuum system generally collects dust and debris via, for example, a dusting brush, conveying it to the air/material receiver separator through a narrow gauge hose. The narrow gauge increases the pressure drop to about 25mm of water column per 300mm of hose, which reduces the amount of material that can be moved at any one time.

The vacuum system’s power requirement is dependent on the total system effect loss. The greater the pipe distance, the harder the pump must work in order to maintain the pick-up velocity. It is for this reason a central vacuum system is designed with multiple drops. This reduces the hose distance, so the strength of pickup speeds can be maintained. In central vacuum systems with a number of drops, it is the number of users the system can support which is the main cost-driver. The greater the number of concurrent users, the greater the differential pressure, resulting in lower pickup speed. Such systems are, however, ideal for the types of tasks found in domestic cleaning situations.

A dust collector and a vacuum system differs in their effect, how they are configured and how the airflow behaves. A dust collector is configured as a number of parts that work together safely, through either:

In brief, it is made up of a hood, an air moving unit, ducting for intakes and exhausts and ducting works. These components vary relative to the client’s requirements, the size of the location, and the substance to be picked up.

The dust collection system is a high volume, low pressure (HVLP) design. This means that the collector is slowly (7 to 30 meters per second) intaking large quantities of airborne particles with a large range of cross-sectional areas.

The narrow gauge of a vacuum hose creates high pressure because of its narrow diameter. A dust collector intakes the air that has been contaminated and draws it into capture hoods, some of which can be as large as 6 meters wide by 6 meters high, or intake ducting throughout a building, which would be used in specific operational or assembly areas.

The dust collector (HVLP) can handle far greater air volumes than a vacuum (LVHP). In brief, vacuum systems are made for precise cleaning and conveying material; however, dust collectors ensure distribution of breathable and clean process air throughout the whole facility.

It follows then that a dust collector processes airborne particles and dust differently from a vacuum system. The dust collector can be facility-wide, portable, or a downdraft/backdraft table. Bear in mind, vacuum systems generally handle precision (high pressure, low volume) and dust collectors generally handle the opposite (high volume, low pressure).

This brief review has clearly set out the disparities between a vacuum system and a dust collector. The former is high pressure/low volume, while the latter is low pressure/high volume. Vacuums are primarily utilised for precise cleaning and the transport of material while dust collectors are used for a specific process filtration or for use in a complete facility.

Conflating the two is not surprising, because most users are not trained in how these systems are used.

We have been providing assistance on dust collectors and industrial vacuum systems in Australia for over 30 years. We have extensive experience in many heavy industries in the design and install of these types of solutions.

If you have any questions in relation to a pneumatic conveying system, feel free to call us on 1300721458 or send us a message via our Pneuvay website contact page or Pneuvay Facebook page.

Get social with us and see the latest news items from:

Vortex Global is proud to appoint Pneuvay Engineering as its sole agent for New Zealand.

Read on to find out how this set a new standard for bulk material handling solution for Australia and New Zealand.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541