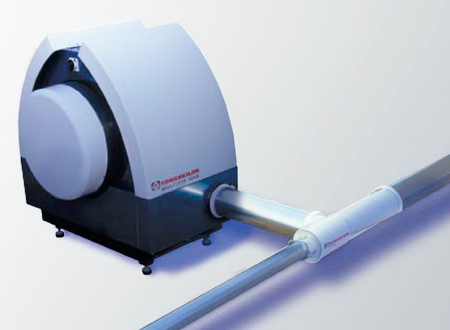

Venturi System

The ITF Inline Venturi system is suitable for conveying continuous edge trim and paper off cuts,

aluminium and plastic from production systems with low to medium production speed.

A compact trim handling system for continuous trim and trim cut.

The ITF Inline Venturi system is suitable for conveying continuous edge trim and paper off cuts, aluminium and plastic from production systems with low to medium production speed.

The ITF Inline Venturi utilises standard Kongskilde modular pneumatic conveying components to transfer process waste (edge trims) and light materials.

The ITF Inline Venturi system is suitable for conveying continuous edge trim and paper off cuts, aluminium and plastic from production systems with low to medium production speed. It utilises standard Kongskilde modular pneumatic conveying components to transfer light materials and process waste, such as edge trims. This technique minimises the wear of the product while giving industries the option to build a cutter into its system. With its capacity with the capacity to cut the continuous trim into its system; thus, reducing

See some of the reasons why Kongskilde ITF Inline Venturis System is hailed by many as the best.

The installation of an ITF Inline Venturi System is simple. The system is based on a modular build-up and the material is vacuumed into the pipe system at the suction point without the need to set up special feeding arrangements. The diameter for the ITF Inline Venturi mainpipe is available as either 80 mm or 100 mm. The main pipe can be branched into pipes with smaller diameter, which makes it possible to evacuate edge trim from several pick-up points.

The ITF Inline Venturi system requires virtually no maintenance, as the material being conveyed in the system never comes in contact with any moving parts.

The ITF Venturi system has been designed to produce maximum suction in the line and at the material pick up point. This is achieved by placing the ITF venturi system as close as possible to the discharge point of the waste material.

The two tables below illustrate the various applications and limitations of the ITF Inline Venturi System in conjunction with different types of blowers.

We offer a wide range of fan, blower and industrial fan products. See our list of products below:

We recently made an exciting visit to Vortex in the USA to enhance our capabilities as a regional agent for their products.

Discover the valuable insights we gained and why we are proud to partner with Vortex!

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags