System Project

We have over 22 years of experience in the Supply of Industrial Vacuum Systems

and have supplied and installed numerous systems throughout Australia.

We supply industrial vacuum system to various industries. We have over 22 years of experience in the Supply of Industrial Vacuum Systems and have supplied and installed numerous systems throughout Australia.

Client: Millmerran Power Station, Queensland

System Description: Central industrial vacuum system

Product for handling:Coal splliage, coal dust and coal fines

Vacuuming of coal spliiage, coal dust and coal fines from within the multiple floors of the building using vacuum points positioned throughout, allowing for the coal to be reclaimed into existing silo.

Open belt conveyors leading to an excessive build-up of coal and coal dust on the floors and horizontal surfaces.

Install a vacuum system to eliminate the manual handling task of shovelling the coal into barrows and taking down stairs and disposing.

Ability to discharge vacuumed coal back into the system for reuse using:

Fully automated discharge system using:

Central vacuum industrial systems for the Millmerran Power Station

The Millmerran Power Station, located near the town of Darling Downs in southern Queensland, is an 850 MW power and considered to be the most energy efficient and environmentally advanced coal-fired projects in Australia. It supplies electricity for about 1.1 million homes and sells all of its electricity into the National Electricity Market (NEM).

It is one of the lowest coal generators of the country, probably due to the coal for the power station coming from the adjacent open-cut Commodore min. This helps lower consumer electricity costs while creating minimal environmental impact on the surrounding land.

Visit Intergen to learn more about the Millmeran Power Station.

Rio Tinto ( Bellbay) is just one of the numerous industries we have supplied with our pneumatic conveying pipework system. In this project, we installed the dust and product hoppers under a common service platform producing a total system that accommodates up to four operators simultaneously and includes a total of 14 points.

The system pipework consists of a network of various sized pipes and the droppers located in the general area of the plant. All pipework is routed according to Pneuvay Constant Velocity theory in order to prevent blockages from occurring. It incorporates two (2) main pipe runs that connects all vacuum points at various locations throughout the plant. This impressive design and capacity equips the pneumatic conveying pipework system with the capacity to discharge from the cyclone vessels into a 2m3 removal skip.

The significant design features of this type of system

are further divided into:

These photos show the vacuum blower mounted on the ground

for easy maintenance and access.

Large Multipoint Vacuum System

The primary cyclone prior to the filterset to remove large particles

An LTV ISO installed at Comalco - Rio Tinto

The Rio Tinto Superintendent on Handover

Shaving the Type of Product Conveyed

Pneuvay Engineering has supplied a number of vacuum cleaning and recovery systems to ALS Chemex for their laboratories in Australia. The most recent case study involves the one for their Adelaide laboratory.

One of the most recent projects for their Adelaide laboratory incorporated some up to the date design changes such as:

We used envelope filters media rather than cartridges. This new arrangement with the Pneuvay Vortex separating cyclone enables

the system to tolerate extremely high dust loadings. As a result,

the filters can tolerate far more abuse and can last as long as

3 to 4 years between changes.

We provided Adelaide Laboratory a complete system to include a receival cyclone providing primary separation equipped with a dust collector and filter hopper assembly. The exhauster is located on the ground while the dust and product hopper is installed on a common frame. The total system can accommodate 4 operators simultaneously and includes a total of 19 points.

Similarly with all Pneuvay Vacuum Systems, the Adelaide Laboratory project is consist of a network of various sized pipes. The droppers are located in the general area and in various locations throughout the plant while the vacuum material is conveyed back to a cyclone vessel, which discharges it into a 200 L bin, together with an exhauster. Ultimately, all pipework will be routed following Pneuvay Constant Velocity Theory to prevent blockages from occurring.

Typical vacuum system Installed at a mining laboratory

with dual discharge silo to reduce noise

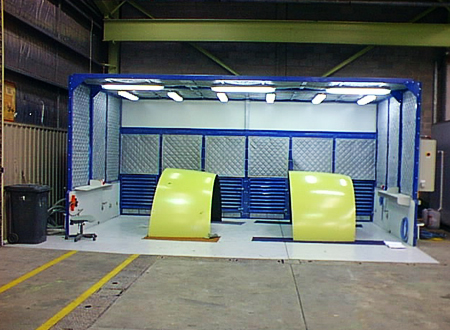

A major airline maintenance facility required a better quality, safe and operator friendly sanding environment. An existing room and system did not provide them with adequate features to ensure the health and safety of the operators. The operational requirement was to ensure that the trained employees were to perform their duty in a new room that provided both a dust capture system attached to their sanders and a dust collection system that provided them with a clean environment

to ensure good visibility.

The design concept of the Hi-Vac system is similar to the Pneuvay system installed at the Ford Motor Company in Campbellfield and displays various innovations. Our solution was to provide six Torit ECB power modules and install them in a freestanding position within a modified Torit /Pneuvay ECB6 room. It also included the option of a special 6-point high performance vacuum system, which is incorporated into the room design for connecting to Riva or Festa sanders.

This Hi-Vac system was also supplied with a set of tools that can be

used for many uses including:

One of the important changes to the standard booth is the use of non-reflective white panels around the bottom of the booth. This helps the operator view the edges of the workpiece against a smooth non-reflective background enabling him to view any imperfections in the finishing work. This has dramatically improved the efficiency and quick quality of the finishing task.

One of many environmental control and glue spray booth used

by airlines bonded structure facilities

Our WA Perth agents Marc Environmental recently purchased from Pneuvay a series of Pneuvay LT blowers and vacuum pumps.

This included:

Pneuvay Engineering's sales of these blowers have been over

100 units in recent times.

Pneuvay LTV 100 Blower

Peerless Holdings recently installed another of Pneuvay's

constant velocity vacuum systems. This system is used for

cleaning up the factory of:

It was specifically designed to vacuum all materials that was

constantly discharged from the receival vessel.

The design of the vacuum system is of paramount importance for the success of this project. Fatty materials would easily block the vessel and cause failure of the entire vacuum system. Therefore, Pneuvay Engineering carefully studied this and produced a system that utilises the Pneuvay Constant Velocity Theory for them to produce a custom fit solution that can be modified to suit difficult situations.

Pneumatic Conveying Vacuum System for Peerless Holdings

Specifically designed vacuum system for Peerless Holdings

One of Pneuvay's specifically designed vacuum systems

used to clean up spills of organic dusts and meat meal

Rio Tinto (Pilbara Iron) recently commissioned Pneuvay Engineering to design and supply a mobile vacuum unit with the following components:

Today, this mobile unit is operating on site at the Pilbara mine without fault. Some of its key features include:

This mobile vacuum rig unit is fully contained

with its own compressor and vacuum blower

The Pneuvay operating panel on a 300 KW Mobile Vacuum Unit

The Pneuvay Mobile Vacuum Unit uses a VSD and can operate through 500mm/80mm/100mm conveying hoses

Set of tools inside the cabinet

Pneuvay builds different sets of units ranging from 30 KW to 200 KW

Photo showing the easy removal of the tipping hopper

at the rear of the mobile unit.

Pneuvay blower inside the vacuum trailer protected from misuse

A Pneuvay mobile vacuum rig used for site cleaning

We recently made an exciting visit to Vortex in the USA to enhance our capabilities as a regional agent for their products.

Discover the valuable insights we gained and why we are proud to partner with Vortex!

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags