See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Friday, May 29, 2020

When it comes to pipe bends vs pipe elbows, are you aware that while every pipe elbow is a pipe bend, most pipe bends are not pipe elbows? Pipe elbows and pipe bends do perform the same function, that is curve and reroute pipework in pneumatic conveying systems. This might explain why 'elbows' and 'bends' are typically thought of as the same; however we will show that this is wrong and that they clearly are not.

Pipe bends vs pipe elbows in pneumatic conveying systems

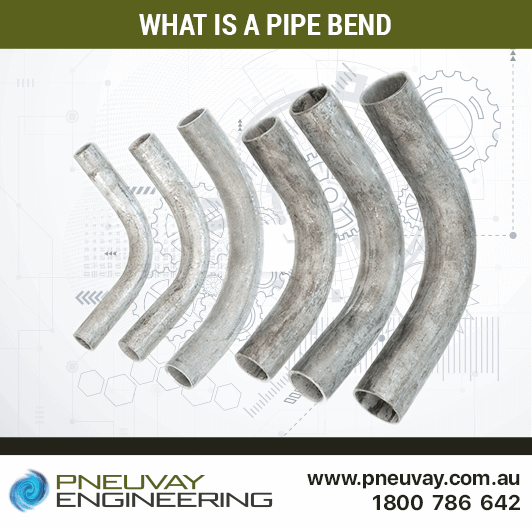

In pipework, a 'bend' connotes an 'offset' and a way of altering direction. The term 'pipe bend' is a general one and does not include engineering references such as curvature or a quantum of angle. Pipe bends are created by use of a specialised machine, which is, in many cases, situated on the worksite. The pipe bending can be achieved by means of either hot or cold process.

The kind of bend is defined by the diameter of the circle that fits the bend divided by the radius of the pipe. Thus a ÐD bend' is one where the circle radius equates to three times pipe diameter. Bends are uncommon under 1.5D. A bend of this kind is a 90-degree right angle, while a ?D bend' gently curves evenly over a long arc between two sections of pipework.

When specifying a pipe bend, the follow parameters are required:

Pipe bends for pneumatic conveying systems come in all standard tube and pipe thicknesses and are constructed with aluminium, carbon steel, stainless or galvanized steel.

What is a pipe bends in pneumatic conveying system

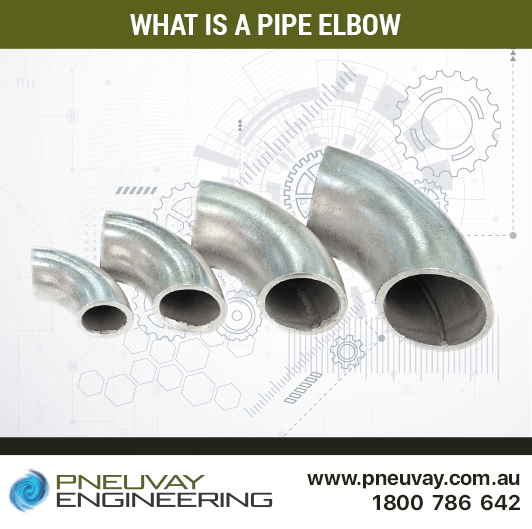

ANSI (American National Standards Institute) specifies a pipe elbow as an angled tube piece designed, created and manufactured according to its strict guidelines. Pipe elbows are classified as either SR (short radius) or LR (long radius) in type.

The curvature (ratio of radius of circle that fits the bend to the pipe diameter) of an SR elbow is 1.0D while an LR elbow is 1.5D. Material being pneumatically conveyed along LR elbows will have a smoother flow compared to SR elbows.

Generally, pipe elbows are made to angles of 45 or 90 degrees, but 30, 60 and bespoke angled elbows can be made. The LR elbow (1.5D) is the most common type utilised, and it can be used in more ways. Further, LRs do not cause as much pressure reduction as SR elbows, although SRs are cheaper and fit into smaller areas.

Elbows in the small and medium sizes are usually manufactured as discrete articles and cast with no seams and range. They range in size from DN15 to DN1200 where DN (nominal diameter) of a pipe is the size of the pipe bore in millimeters. So the largest SR elbows used commercially have a nominal diameter of 1219mm (48 inches). Larger elbows are fabricated by butt-welded steel plates and range in size from DN500 to DN2500. Their manufacture is governed by 'ASME B 16.9 - Factory-Made Wrought Buttwelding Fittings’.

What is a pipe elbow in a pneumatic conveying system

Pipe bends and pipe elbows are mostly differentiated by how they are manufactured. In all other respects they are similar, insofar as the elbows are simply a specific kind of bend. This is apparent from the terminology that ‘pipe bend’ is the overarching term, while ‘pipe elbow’ is the technical one. In looking at the more subtle differences between one and the other, it is apparent that:

The amount of curvature is the fundamental contrasting factor between pipe bends and elbows. A curvature radius of 1D to 1.5D is typical in elbows, whereas the curvature radius in bends is commonly at least 1.5D. This is primarily because the bending of a pipe affects the pipe wall thickness. The more acute the angle, the greater the thinning of the pipe wall. This will reduce the amount of pressure the pipe work can contain. Further, because material does not travel as smoothly in short curves as in long curves, longevity of the inner surface in a tight pipe bend in surviving wear and tear will be shortened.

An industry leader in the design and supply of pneumatic conveying systems, Pneuvay is ideally placed to help you with pipe bends, pipe elbows and pipework. Our clients include many large, major organisations that have turned to us for the design and successful provision of best fit solutions that make use of pipe bends and pipe elbows in situations such as:

If you need help with pipe bends and elbows, or have any have questions in regards to pneumatic conveying pipework design, feel free to call on 1300721458 or contact us. You can even send us a message via our Facebook page if you like.

Get social with us and see the latest news items from:

We recently made an exciting visit to Vortex in the USA to enhance our capabilities as a regional agent for their products.

Discover the valuable insights we gained and why we are proud to partner with Vortex!

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541