See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Wednesday, September 20, 2023

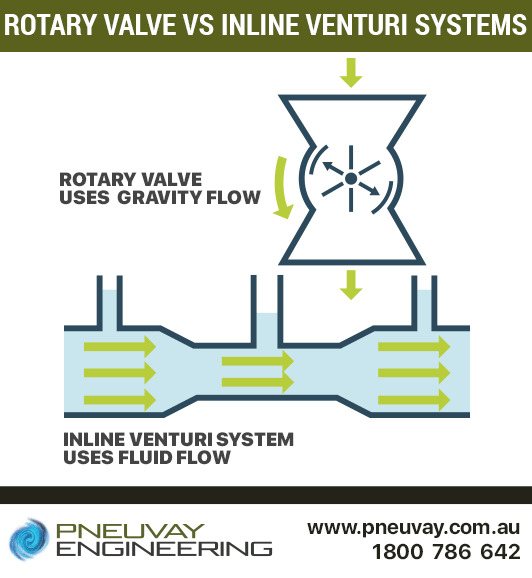

Rotary valves and venturi systems are commonly used in pneumatic conveying systems. They play different roles though, and there are two major differences in how they are applied.

Understanding the role of rotary valves and venturi systems in pneumatic conveying

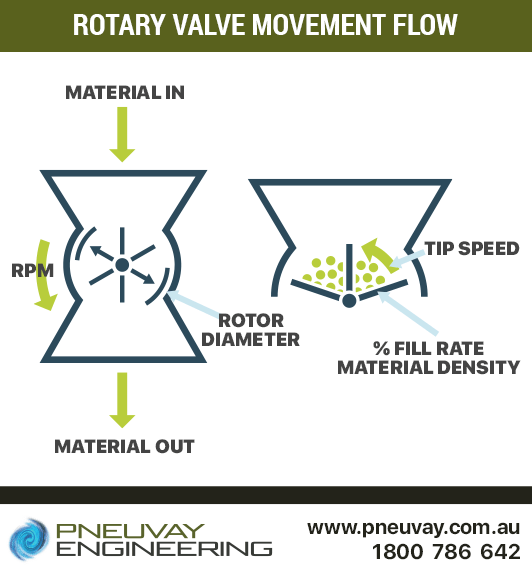

A rotary valve is a compact mechanical device using gravity flow for continuous transfer of bulk powders or granules. It is considered a simple machine because it has only one moving part. This is a multi-vane rotor that revolves in close contact with the rotary valve housing. The other non-moving parts include an inlet on top and an outlet at the bottom. Read more about the rotary valve.

Parts and operation of rotary valves

A rotary valve is used for the following functions:

The industries that use rotary valves include:

Rotary valves have several major industrial applications.

Rotary valves are placed under silos, hoppers or other container systems. They are used to control bulk solid discharge from these units and to feed devices like heliflows, flexible screw conveying, pneumatic conveyors and mixers.

Rotary valves can also be placed under a cyclone. This applies a pressure seal between the storage and conveying systems so material flows uniformly from the outlet.

Dust collection systems utilise rotary valves to unload dust. They are used to transition material from one pressurised point, such as a dust collector, to an unpressurised point, such as a drum or bin. The valve seals a pressurised system against loss of air volume and air pressure. This allows dust from hoppers, bins or silos to be captured and returned to the material processing or conveying system.

Rotary valves control the rotor speed of the airlock, which allows volumetric measurement of both powdered and granular bulk materials.

Rotary valves are also used to feed pneumatic conveying lines from hopper, silo, cyclone and big bag discharge stations. This aids in preventing air leakage from the conveying line while maintaining constant feeding of powders or granules.

Rotary valves also aid pneumatic conveyors feeding from silos, hoppers and screw feeders by sending bulk materials into airlocks before being moved into another device. This enables their use as an airlock for pneumatic conveyors.

Read up more on the rotary valves we can supply rotary valve.

A venturi system is a section of pipe with a cone-shaped constriction that transports materials, such as continuous edge trim, offcuts, roll ends, blow and injection moulded products and waste. With no moving parts, it is considered the simplest of machines.

Unlike rotary valves that rely on the properties of gravity flow, venturi systems rely on the properties of fluid flow. The mechanics explaining how a venturi system works are based on the conservation of energy in fluid flows, as given by the Bernoulli equation.

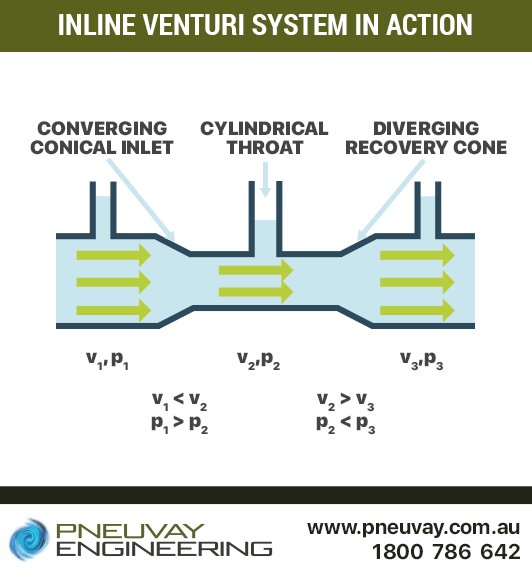

A venturi system has the following features:

Venturi system in action showing airspeed and air pressure changes

See how Bernoulli principle explains how air entering a constriction in a tube will increase its speed but decrease its pressure

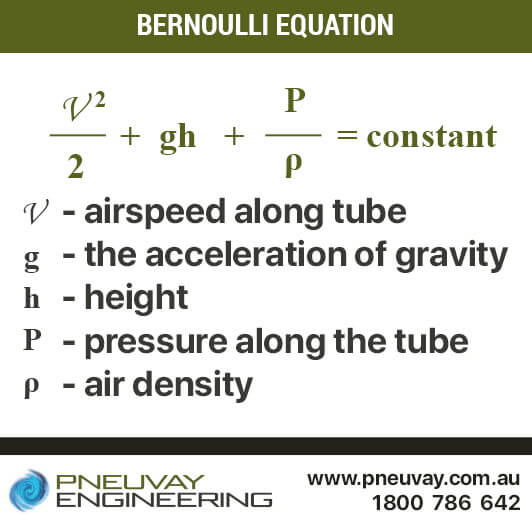

Unlike rotary valves that rely on the properties of gravity flow, venturi systems rely on the properties of fluid flow. The mechanics explaining how a venturi system works are based on the conservation of energy in fluid flows, as given by the Bernoulli equation.

The Bernoulli equation states that the sum of all forms of energy in a fluid (including gases) flowing along an enclosed path is the same at any two points in that path. That is, energy within the fluid is conserved. As a consequence, fluid passing smoothly through a pipe with constrictions will be subject to various changes in speed and pressure in order to maintain energy conservation.

Bernoulli equation as applied to venturi systems

See how the Bernoulli equation is used to describe the movement of a fluid through a pressure difference. You can also watch on youtube too.

A venturi system is typically used to transport suitable materials through a pipe using an air vacuum effect. It is used in transporting materials such as:

The industries that use venturi system include:

Transport of low density granules (EPS and EPP), blow moulded items, continuous cut trim in medium speed productions and shredded material from small shredders using suction. The controlled airspeed is used to minimise the impact on the conveyed items.

Different types of material being transported in an air flow can be separated through pipe diverters and changes in air pressure. This includes situations like removing flash and rejects from blow moulding machines.

A venturi system is used in applications that require the removal of gases on a continuous basis while maintaining pressure at a stable pressure level. Examples of this include removing smoke from machining or welding areas.

Venturi systems with jet pumps can be used for the evacuation of gases from tanks or vessels. Gas is steadily pulled from the tank or vessel until a desired lower pressure is achieved. The lowering of pressure in the tank or vessel can be used to purge detrimental gases.

Kongskilde has unrivalled expertise in the handling of process waste produced in various industries. This includes their various inline venturi systems.

Despite there being many manufacturers of venturi systems, Kongskilde leads the competition. Its use of high quality materials, precision construction and having no moving parts means there is almost zero maintenance.

It has the following features:

We supply Kongskilde inline venturi systems

We now come to the big question: what system should I use for my pneumatic conveying system?

When the pneumatically conveyed materials are low density, continuous lengths and odd shapes made of paper or plastics that need to be transported, a venturi system is needed. Such materials include continuous edge trim, offcuts, roll ends, blow moulded and injection moulded products and waste.

When, however, materials to be pneumatically conveyed are bulk powders and granules that need to discharge in a continuous and controlled fashion, then rotary valves are required.

Do you need help figuring out the best system to use for your factory and plant? We are happy to help you. Feel free to send us a message from the Pneuvay website contact page or our Facebook page.

Get social with us and see the latest news items from:

We recently made an exciting visit to Vortex in the USA to enhance our capabilities as a regional agent for their products.

Discover the valuable insights we gained and why we are proud to partner with Vortex!

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541